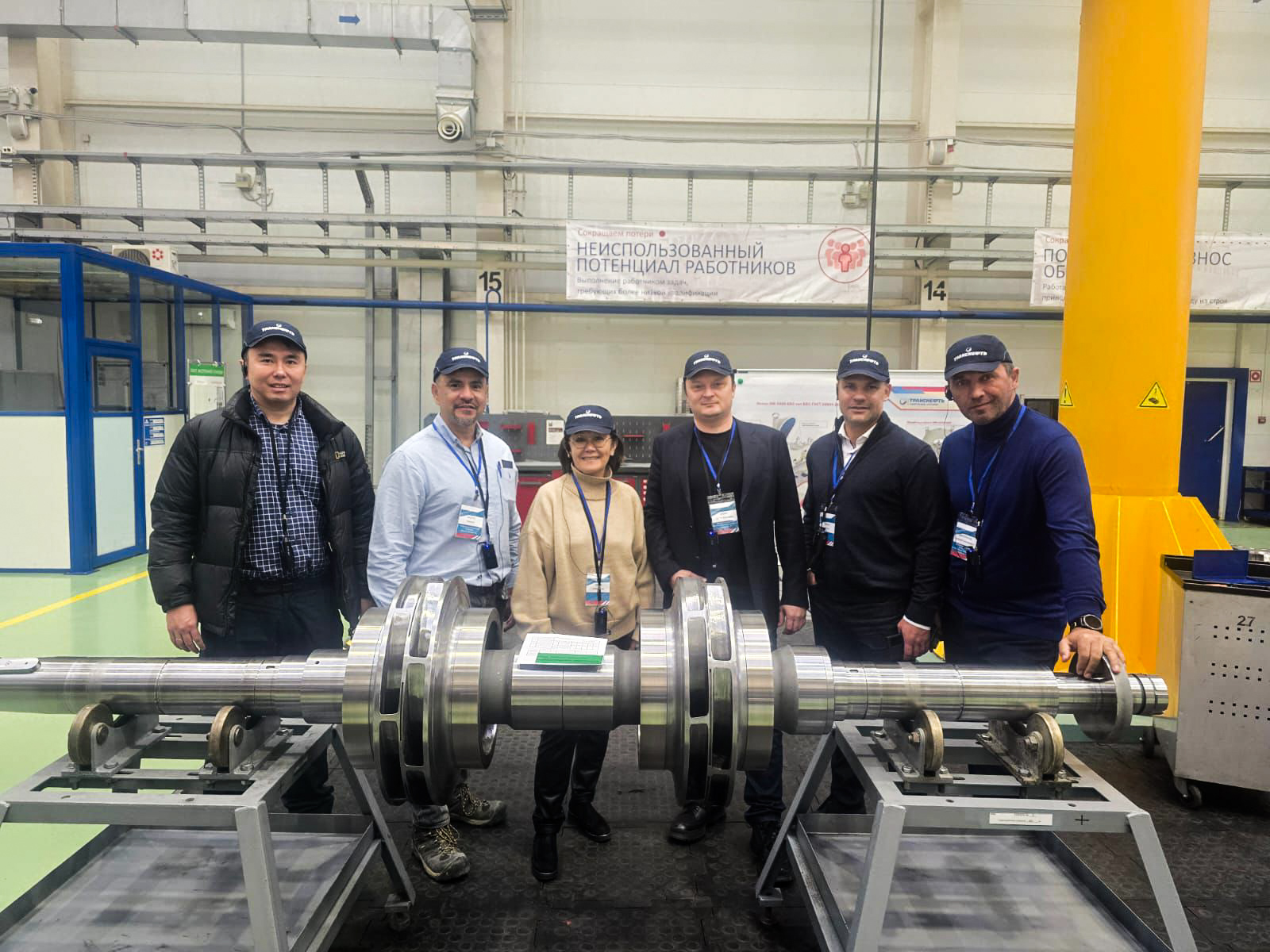

On 11-13 November 2024, in Chelyabinsk, the delegation of CPC-R specialists and CPC Shareholder representatives visited the production sites of Ural Dynamic Machines, which manages the plants - Transneft Oil Pumps and Russian Electric Motors. The working visit was under the Program to replace mainline pump units driven by gas turbines implemented by the Consortium.

The delegation got acquainted with the work of the design bureau and testing center, visited the production sites of Transneft Oil Pumps and Russian Electric Motors, and also the foundry and forging production of the UDM partners' group located on the premises of the Stankomash industrial park. In the course of a visit to the production site of Transneft Oil Pumps, the delegation was demonstrated the manufactured parts of the first pilot pump unit manufactured under the contract with CPC (pump casing, pump rotor with impellers) and plate elastic coupling. Tests of the scale model of the flow part of the prototype pump developed by Transneft Oil Pumps showed compliance with all design Q-H parameters.

CPC specialists and its Shareholders saw for themselves that the Transneft enterprises involved in making the prototype MPU had all the necessary resources, labor and means to manufacture the highest class pumping equipment meeting the GOST 32601-2022 and API 610 requirements. The manufacturing of all components is fully localized, and strict quality control is ensured at all stages of manufacturing in compliance with high standards of occupational health and safety at work.

As a reminder: the Program to replace mainline pump units driven by gas turbines will cover three CPC PSs in the Russian Federation - APS-4A, Komsomolskaya PS and Kropotkinskaya PS. New buildings for mainline pumps with units installed in parallel with necessary associated structures will be constructed at each of the stations.

Transneft Oil Pumps and Russian Electric Motors plants face the task of manufacturing pump units with electric motor with extended Q-H parameters, different from the standard line of equipment manufactured by Transneft companies. Their introduction will increase the overall flexibility of the CPC pipeline system, both when pumping incremented volumes and when reducing flow rates, and will also make it possible to standardize the line of operated equipment and minimize spare parts inventory.

For information:

CPC Pipeline System is one of the major projects in energy sector in the CIS. The length of the Tengiz – Novorossiysk pipeline is 1,511 km. This route transports over two-thirds of all Kazakhstan export oil, and crude from Russian oil fields, including those in the Caspian Region. CPC Marine Terminal is equipped with three Single Point Moorings (SPM) that allow to load tankers safely at a significant distance offshore.

CPC Shareholders: Russian Federation – 24 %, IC CPC Company (LLC) – 7%, NC KazMunayGas JSC – 19%, Kazakhstan Pipeline Ventures LLC – 1.75%, Chevron Caspian Pipeline Consortium Company – 15%, Lukoil International GmbH - 12.5%, Mobil Caspian Pipeline Company– 7.5%, Rosneft-Shell Caspian Ventures Limited– 7.5%, BG Overseas Holdings Limited– 2%, Eni International N.A. N.V. S.ar.l. – 2% and Oryx Caspian Pipeline LLC – 1.75%.